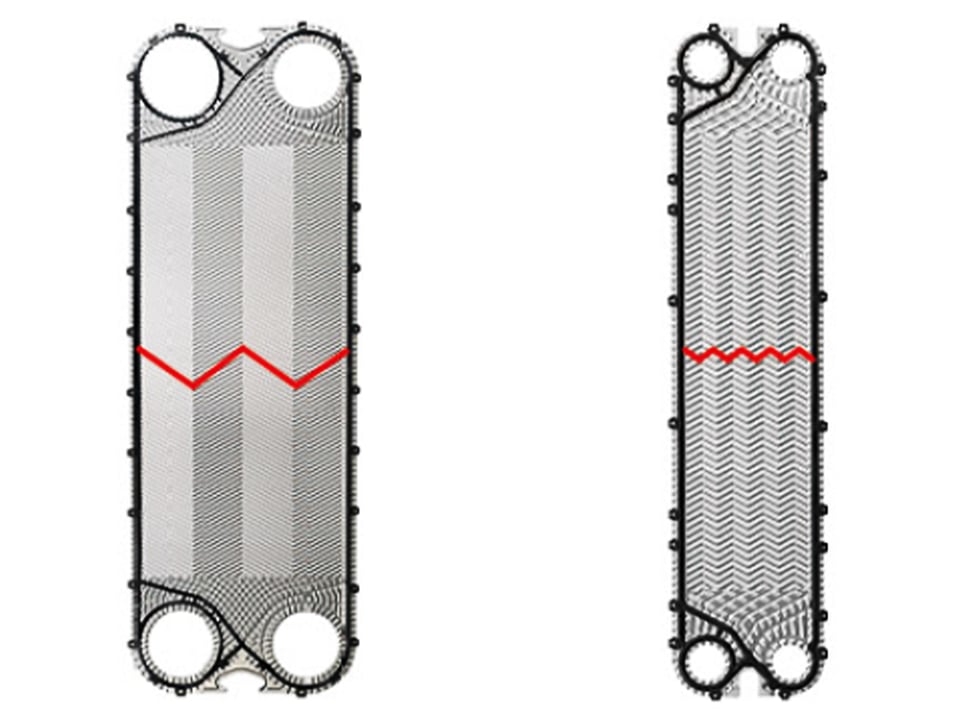

High-theta Plate

- Maximizes heat transfer

- High turbulence = better efficiency

- Ideal for close temperature approaches

- Higher pressure drop

Products and Solutions

High-efficiency heat transfer. Flexible configurations. Easy maintenance. All in a compact, field-proven design.

Built for performance and flexibility, LHE’s gasketed plate and frame heat exchangers deliver efficient thermal transfer, easy serviceability, and cost-effective operation.

Every unit is engineered to your specs and designed to evolve with your process over time.

Our gasketed design separates hot and cold fluids using thin, corrugated plates — each sealed by a replaceable gasket. These plates are stacked into a frame that’s easy to open, adjust, and clean.

Add or remove plates to match changing capacity needs. Perform gasket swaps without disassembling the entire unit. It’s a design made for uptime, adaptability, and total service access.

As two fluids pass through alternating plate channels, heat transfers through the thin metal surface — no mixing, no direct contact.

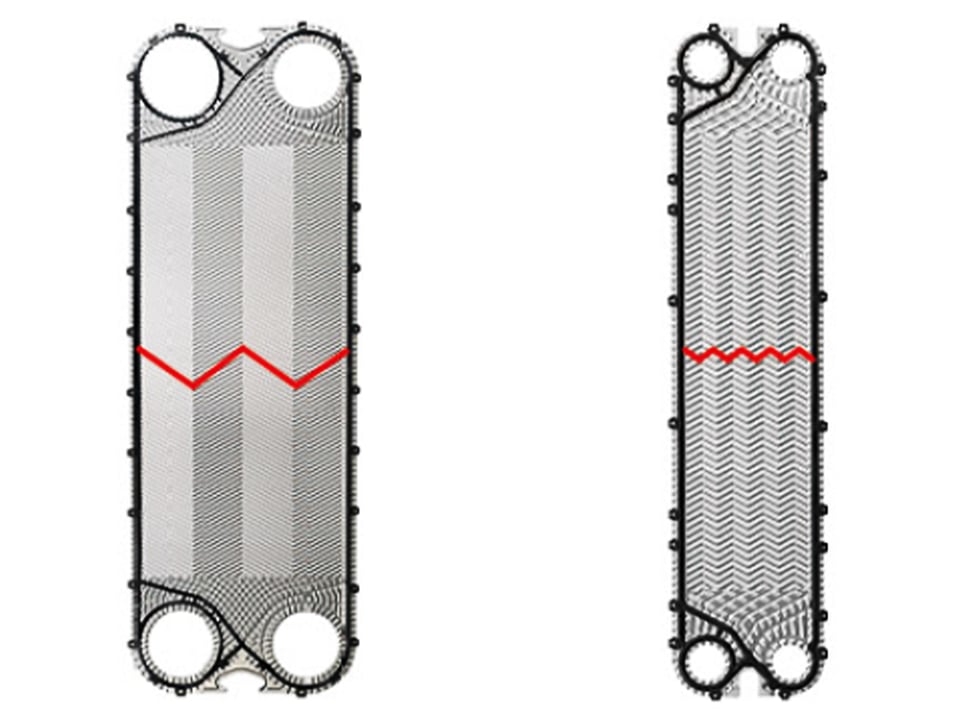

The corrugated pattern creates turbulence at low flow rates, increasing thermal efficiency and reducing fouling. That means you get better heat recovery with less energy and fewer cleanings.

Three types of channels are available with the high theta and low theta plates.

Corrugated plates create turbulence even at low flow, achieving up to 5 times the thermal efficiency of shell-and-tube exchangers.

Our Gasketed Plate and Frame Heat Exchanger are 20–30% smaller than traditional designs. Fit more performance into less space.

Turbulent flow minimizes build-up and extends maintenance intervals.

Configure counterflow, co-current, and pressure drop options to match your process.

Tight stacking and insulation keep thermal losses to a minimum.

Maximize heat recovery with plate geometry optimized for minimal ΔT.

Our Gasketed Plate and Frame Heat Exchanger is easy to disassemble and reassemble for gasket or plate replacement. Adding plates to increase capacity can be done quickly with minimal downtime.