Industries & Applications

Heat Exchangers for Tankers

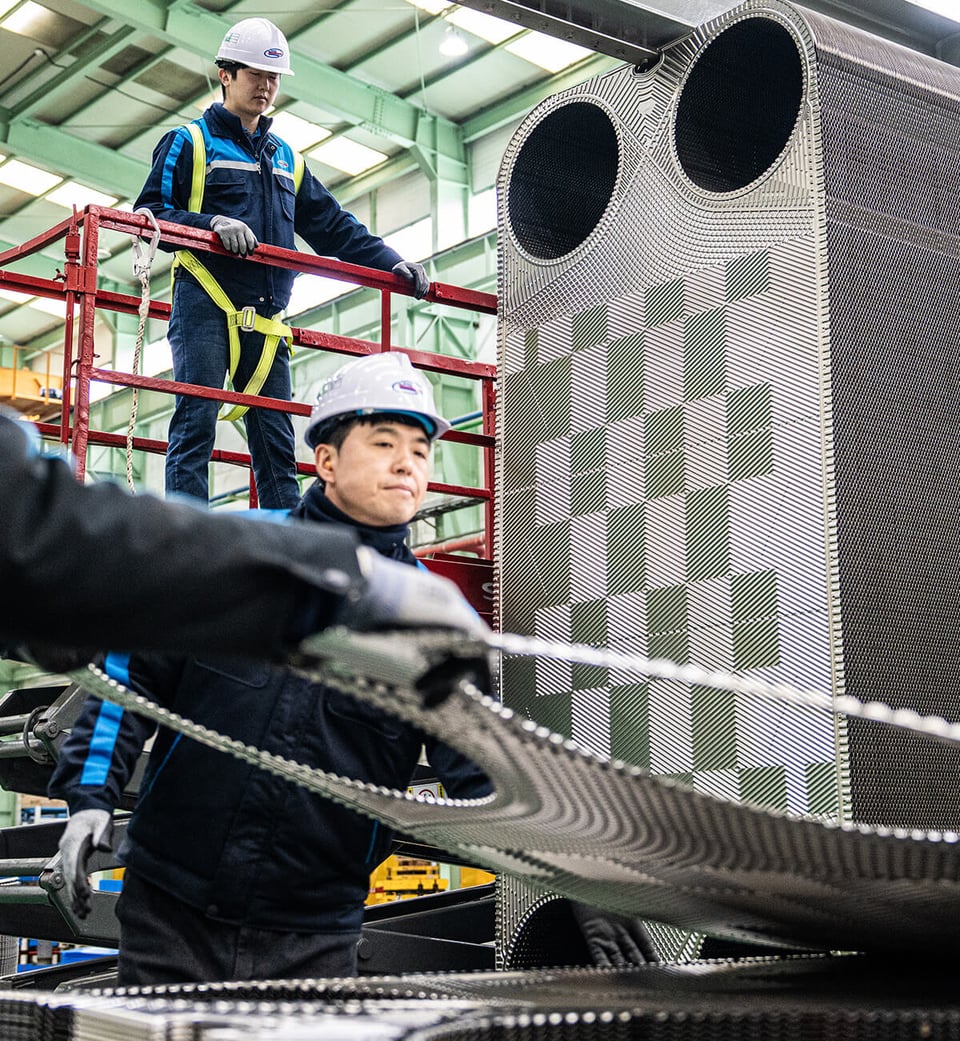

Tanker operations place high demands on thermal systems; from inert gas systems and lube oil cooling to cargo handling and fuel preparation.

LHE designs heat exchangers that match your spec and process, combining high transfer rates, marine-grade durability, and a compact footprint. We build for real-world operation, with global service and proven lifecycle value.

Designs that stay reliable under pressure

Whether you’re outfitting a new vessel or replacing legacy units, we help you hit performance targets while managing space, cost, and cleaning requirements.

- Engineered for glycol, seawater, lube oil, and hazardous cargo streams

- Strong corrosion resistance and marine-optimized materials

- Compact form factor for engine room and utility spaces

- High efficiency at low temperature differentials

Supporting performance across tanker systems

Reduced fouling and cleaning time

Right materials from the start

Faster design integration

Built to compare and designed to fit

High efficiency, low footprint

We balance transfer performance with space constraints better than traditional shell-and-tube or oversized plate options.

Proven marine lifecycle reliability

Used across LNG carriers and chemical tankers, our exchangers perform in long-cycle engine duty and corrosive service alike.

Responsive technical partnership

You’re not left waiting. Our thermal and mechanical teams are integrated, fast-moving, and local where it matters.

One supplier, complete coverage

We provide both welded and gasketed units under one roof, so you don’t need multiple vendors to handle different pressure classes.