Industries & Applications

Heat Exchangers for Bulk Carriers

Bulk carriers face unique challenges: fluctuating loads, long intervals between ports, and limited access to onboard service. Your cooling systems can’t just perform well — they have to adapt.

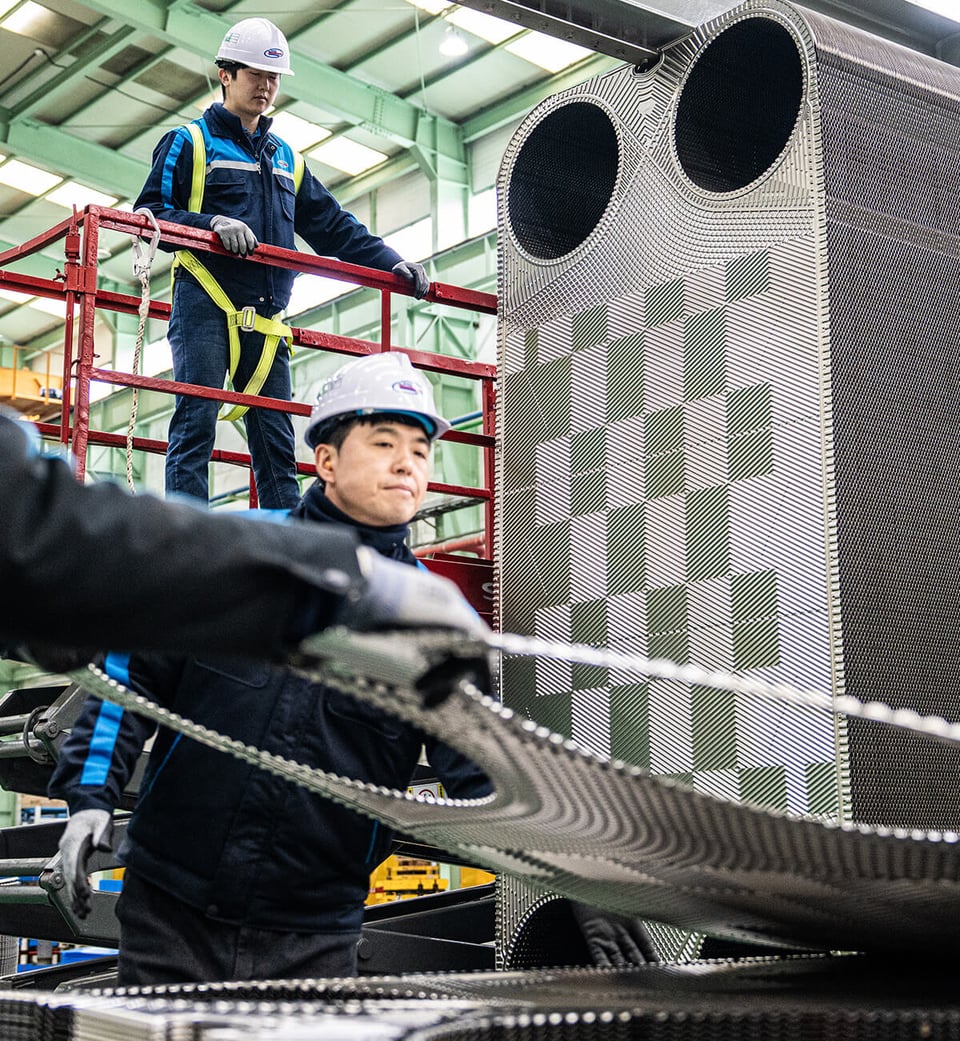

LHE welded and gasketed heat exchangers are designed to support consistent operation throughout ballast shifts, full cargo voyages, and varying ambient conditions — without oversizing or excess maintenance.

Stability you can trust across every voyage

We build plate heat exchangers that match the real operating conditions of bulk carriers — not just ideal duty points on paper.

- Thermal performance tailored to shifting ballast and cargo profiles

- Space-saving frames that integrate into new builds and retrofits

- Plate materials selected for marine-grade corrosion resistance

- Modular construction for easier onboard access and maintenance

- Consistent QA across units for performance you can trust fleet-wide

Keeping cooling systems reliable between every port

Fit tight spaces

Reduce manual cleaning

Enable energy savings

Proven thermal stability for long-haul operations

Designed for real-world variation

Your routes, cargo states, and ambient temperatures change — our sizing and layouts are based on actual operating data.

Compact without compromise

We don’t shrink size at the expense of performance. Our designs protect flow rates, reduce pressure drop, and maintain stable output across duty cycles.

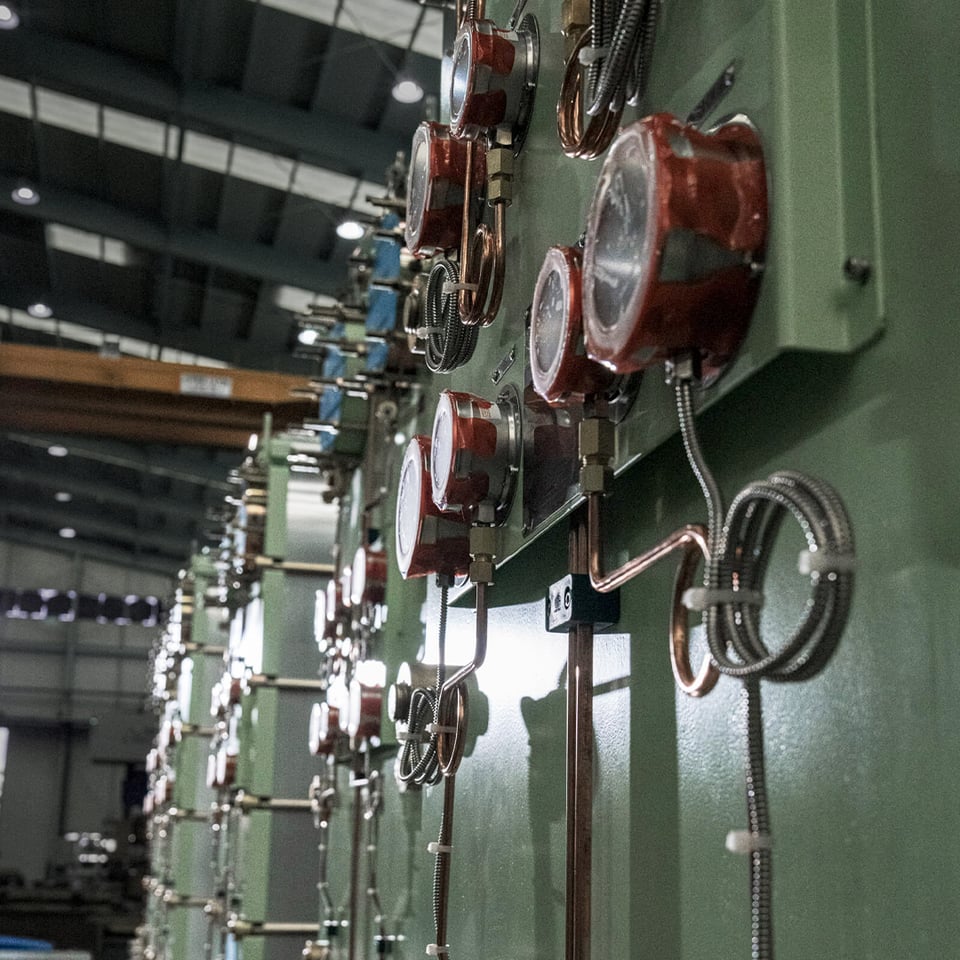

Fleet-level build consistency

Using automated forming and QA processes at our Korean facility, we deliver exchangers that perform the same across vessels and engine configurations.

Support wherever you operate

LHE offers cross-brand service for all gasketed plate & frame heat exchangers, cleaning, and reconditioning worldwide. That means fewer vendor contacts and faster turnarounds when it counts.