Industries & Applications

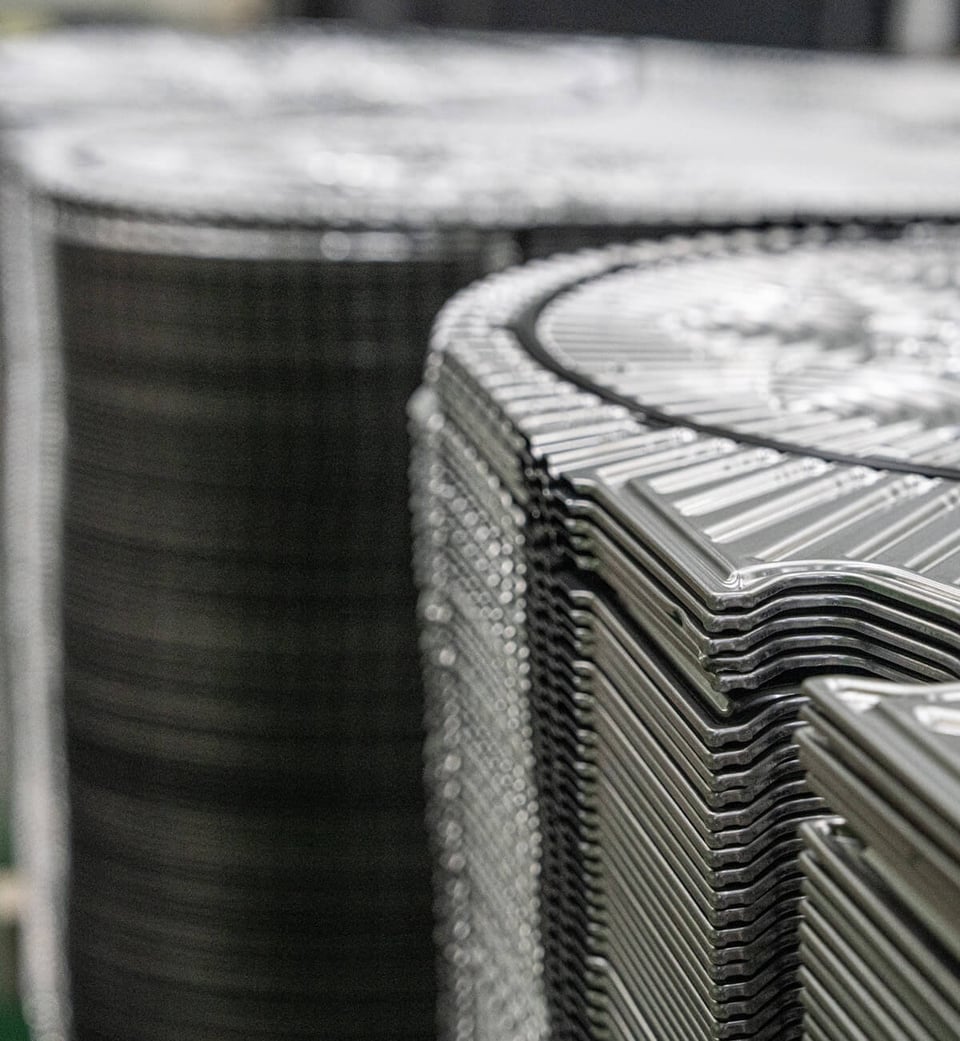

Heat Exchangers for the Energy Process Industries

We propose optimized, application-specific gasketed or welded heat exchanger designs for your process conditions — engineered to reduce fouling, stabilize performance, and simplify maintenance. From FEED to final delivery, we provide comprehensive support with fast technical response.

Heat exchangers optimized for process environments

Our heat exchangers in Energy Process applications

Refining & Petrochemicals

We design heat exchangers that optimize energy recovery, reduce maintenance, and meet specifications across cooling, condensation, and heat recovery loops.

Power

Feedwater, condensate, and utility systems demand uptime under scaling risk. We configure compact, pressure-stable designs built for thermal efficiency.

Oil & Gas

From separation to recovery, we deliver heat exchangers tailored to meet your pressure limits, safety specifications, and media variations.

Mining, Metal & Paper

We help you reduce fouling and extend uptime in abrasive or high-solid loops, with serviceable heat exchangers designed for harsh plant conditions.

Chemicals

Precise temperature control, corrosive fluids, no room for downtime — we build for all three. Our designs align with your cleaning routines and safety thresholds.

Sustainable Energy & Alternative Fuels

New fuels, tighter footprints, tougher standards. We support thermal integration with exchanger designs for feedstock, waste heat, and retrofit constraints.

Delivering performance, precision, and service

Thermal design optimization

We configure each heat exchanger based on your fluids, fouling risks, duty cycles, and pressure loss limits — so you get stable performance with minimal cleaning.

Project and spec support

Whether you're in FEED or handling end-user approvals, we help you move faster with compliant drawings, submittals, and fast-response engineering.

Material and configuration flexibility

Need custom alloys or tighter geometry? We help you choose the right materials and plate layouts based on corrosion risk, flow variation, and specification thresholds.

Servicing every GPHE brand

Running different OEMs across your plant? We clean, inspect, and recondition gasketed plate & frame heat exchangers from any major brand, so you can reduce downtime without replacing equipment.