Industries & Applications

Heat Exchangers for Marine & Shipbuilding

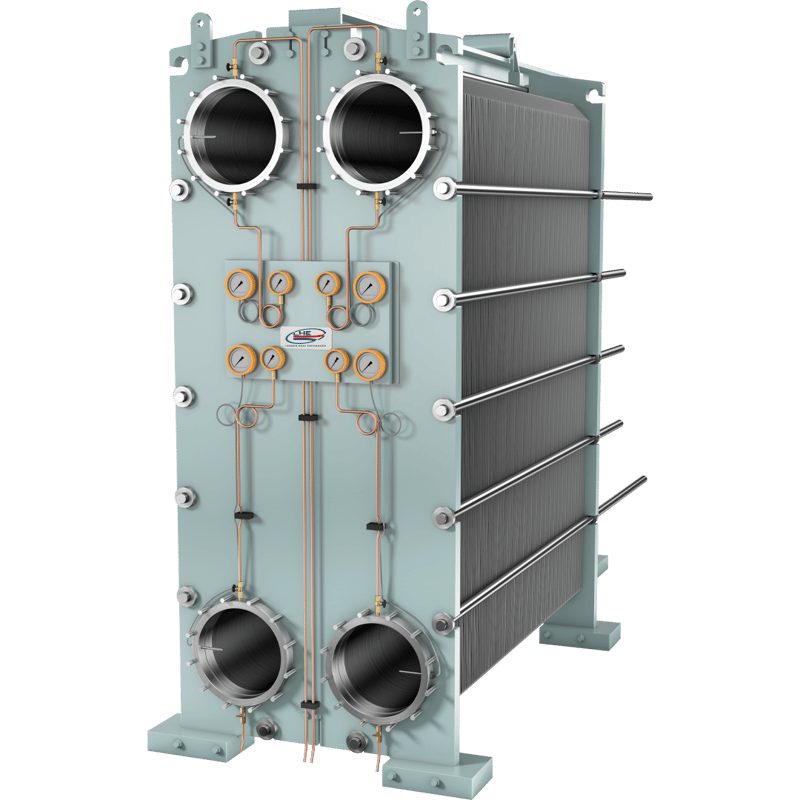

Whether you're handling cryogenic fuel, seawater cooling or onboard utility systems, your vessel's heat exchanger needs aren't one-size-fits-all.

That's why we design compact, corrosion-resistant plate heat exchangers to match marine classification requirements and vessel layout constraints, and to reduce costs. With automated manufacturing and fast-response support, we deliver solutions that perform — and last.

Heat exchangers engineered for marine operating conditions

Our heat exchangers in Marine and Shipbuilding applications

LNG / LPG Vessels

We help you meet fuel system requirements with heat exchanger designs made for pressure control, rapid transitions, and space-constrained installations.

Container Ships

You need reliable cooling across main engines, generators, and auxiliaries. Our designs fit tight engine rooms, reduce fouling, and simplify maintenance.

Tankers

Handling hazardous or corrosive fluids? LHE delivers corrosion-resistant solutions built to integrate seamlessly with your inert gas and seawater systems.

Bulk Carriers

We optimize your heat exchanger for cleaning efficiency and reliability under fluctuating load and ambient conditions, such as long cycles and tight schedules.

Offshore Vessels

From FPSO topsides to subsea skids, we tailor heat exchangers to withstand wave loads, media variability, and weight constraints common in offshore environments.

Other Commercial Vessels

Standardized or customized to fit your needs — LHE supports thermal duties on ferries, fishing vessels, tugs, and more, with reliable, easy-to-integrate designs.

Navy (Government) Vessels

Quiet, durable, and spec-compliant heat exchangers for propulsion and onboard systems. Designs that meet defense-grade performance and uptime expectations.

Heat exhangers for all your needs

Fuel Gas Supply Systems (FGSS)

Our heat exchangers support LNG-based fuel systems with precise control over heating and cooling cycles. Designed for thermal stability and compliance with decarbonization trends.

Thermal design optimization

We customize plate geometry, flow configuration, and material specs to match real operating conditions. The result: better heat transfer, smaller footprint, and less fouling.

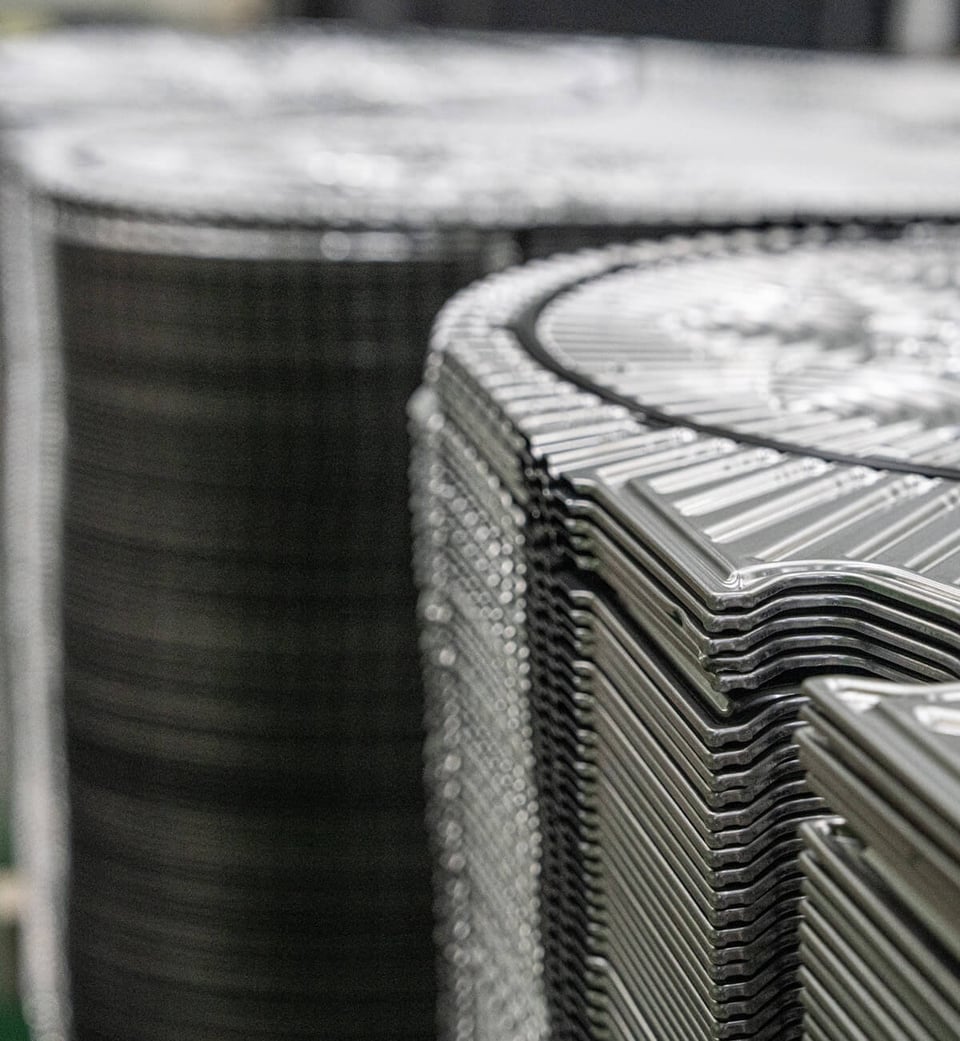

Manufacturing and QA

Produced in Korea using automated presses and proven QA systems, our units offer consistent performance, reliable lead times, and strong alignment with shipyard workflows.

Servicing every GPHE brand

We supply parts and deliver expert service for every gasketed plate & frame heat exchanger brand. With LHE, you get full coverage from one trusted source, regardless of supplier.