Lower your energy bill

Our exchangers reduce compressor load by maximizing thermal efficiency, helping you cut operating costs without compromising performance.

Industries & Applications

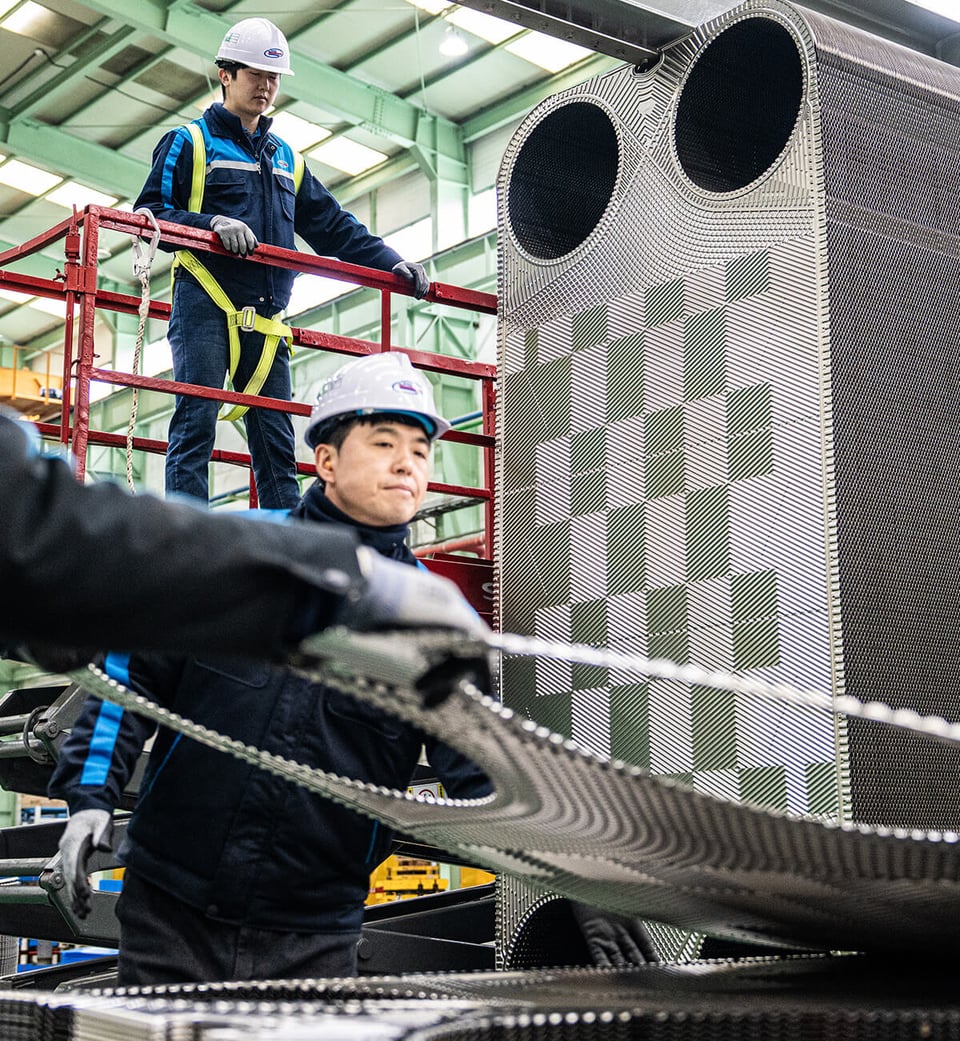

Refrigeration systems demand heat exchangers that save energy, fit into tight spaces, and stay reliable under continuous operation.

From ice rinks and cold storage to pharmaceuticals and process industries, LHE provides gasketed and welded plate heat exchangers designed for your demanding cooling and condensation duties.

Our exchangers are engineered to cut operating costs, handle natural refrigerants like ammonia and CO₂, and to keep downtime short.

Our exchangers reduce compressor load by maximizing thermal efficiency, helping you cut operating costs without compromising performance.

Compact welded and gasketed designs deliver high capacity in a small footprint, ideal for facilities with limited room.

Corrosion-resistant builds handle the demands of food plants, logistics centers, and outdoor systems.

CIP-ready designs meet international hygiene standards, essential in food, beverage, and pharmaceutical facilities.

Engineered for consistent temperature control, even in high-load or sensitive environments.

We tailor exchangers to ice rinks, meat processing & cold storage facilities, marine refrigeration, and more — not generic one-size-fits-all designs.

Our exchangers are built to handle ammonia and CO₂, supporting long-term sustainability and compliance.

Our designs deliver both small footprints and high pressure tolerance — where other models may fall short.

We design to international sanitary and safety standards, giving you confidence in food, pharma, and biotech environments.

Choose GPHE models for easy disassembly and cleaning, or SPHE models for leak-free, long-life durability.